Client Background

- Our client for this project is a leading Australian based producer of plant-based meat substitutes.

- This company is on a sustainability journey, evolving at a rapid pace with a focus on quality, efficiency, and sustainability.

Project Overview

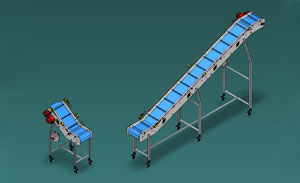

The scope of works for this project was to design, manufacture and deliver conveyors to complement an updated layout and upgrade of the incoming goods area.

Solution

As part of this project our Design Engineers worked closely with the customer and completed a full and complete design analysis to understand the functionality and end requirements of the production line. As part of this process our Design Engineers were able to review the collated information and provide design recommendations to assist the customer with its sustainability, efficiency and quality focus.

During the design analysis phase our engineers were also able to review requested materials and provide further recommendations on the suitability of materials for the intended use. After careful consideration Jarlam was able to provide an alternative recommendation for the belting on this conveyor, a recommendation that what was welcomed by the customer and resulted in a simplification of design, increased hygiene and a reduction in ongoing maintenance.

On completion of the design review Jarlam engineers were able to generate a full 3D design concept in AUTOCAD and present this to the customer for review. As an added advantage to the 3D concept the customer was then able to utilize the 3D concept to review the proposal in real time and engage with the end user to further refine the proposed design.

Our engineers developed full fabrication drawings that were then passed onto our on-site workshop team, who provided high quality, low maintenance conveyors with a proven hygienic design all on time and within budget.

Benefits / Outcome

We are proud to be a part of the sustainability journey that our customer has chosen. The designed conveyors have resulted in the increased hygiene of the line and improved the overall efficiency and functionality of the production line.

The recommended materials have helped with a more user-friendly design and resulted in a reduction of down time for cleaning, inspections and maintenance.

Innovation

100% Customer Satisfaction

Increased Cleanliness and Hygiene