In today’s fast-paced world, technology continues to revolutionise industries and transform the way we work. One such technological advancement that has significantly impacted engineering and architectural drafting is Computer-Aided Design (CAD). CAD technology, used in conjunction with CAD software or CAD programs, has revolutionised the design and manufacturing process, providing numerous benefits for businesses across various sectors. Jarlam Australia, a leading engineering and manufacturing company, understands the advantages of CAD design and utilises this cutting-edge technology to deliver innovative solutions for its clients.

Computer-Aided Design (CAD) in a Nutshell

At its core, Computer-Aided Design (CAD) is a digital design process that utilises specialised CAD software or CAD programs to create, modify, analyse, and optimise designs. CAD technology has revolutionised the field of engineering and architectural drafting by providing powerful tools and features that enable precise and efficient design creation, visualisation, and analysis.

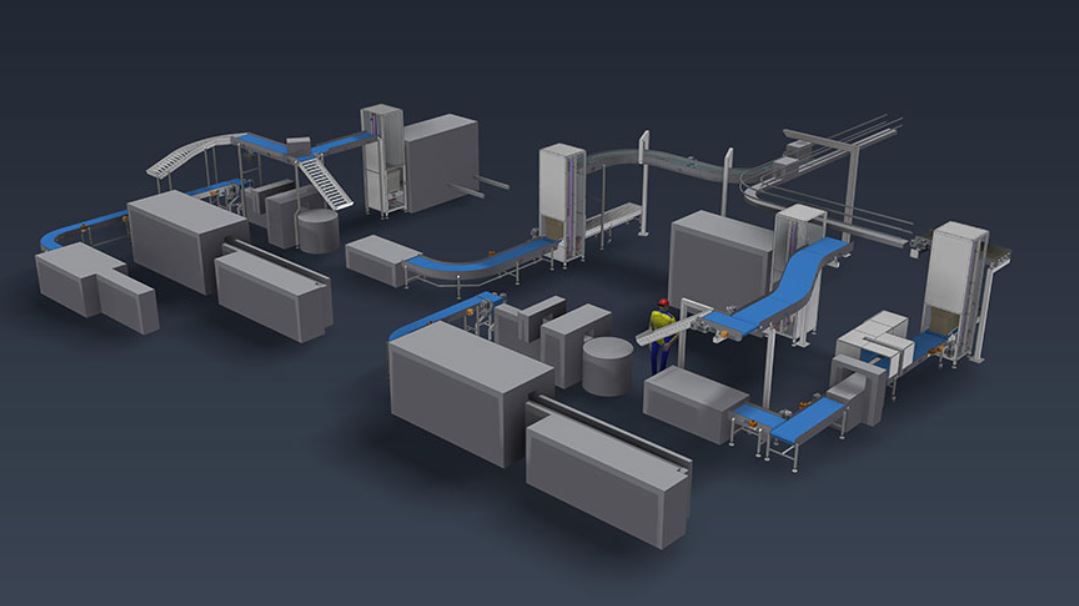

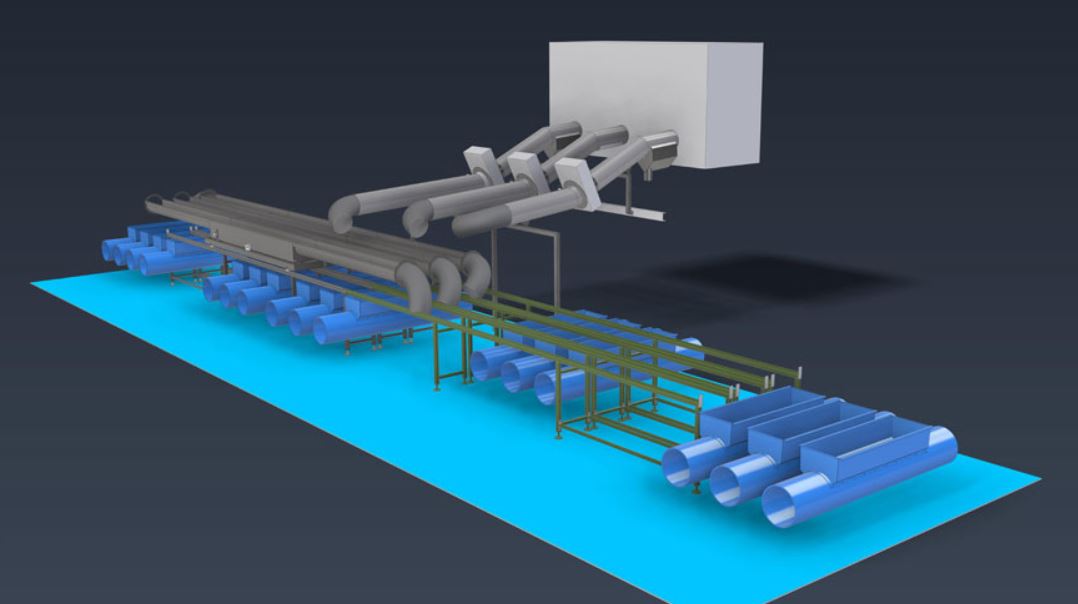

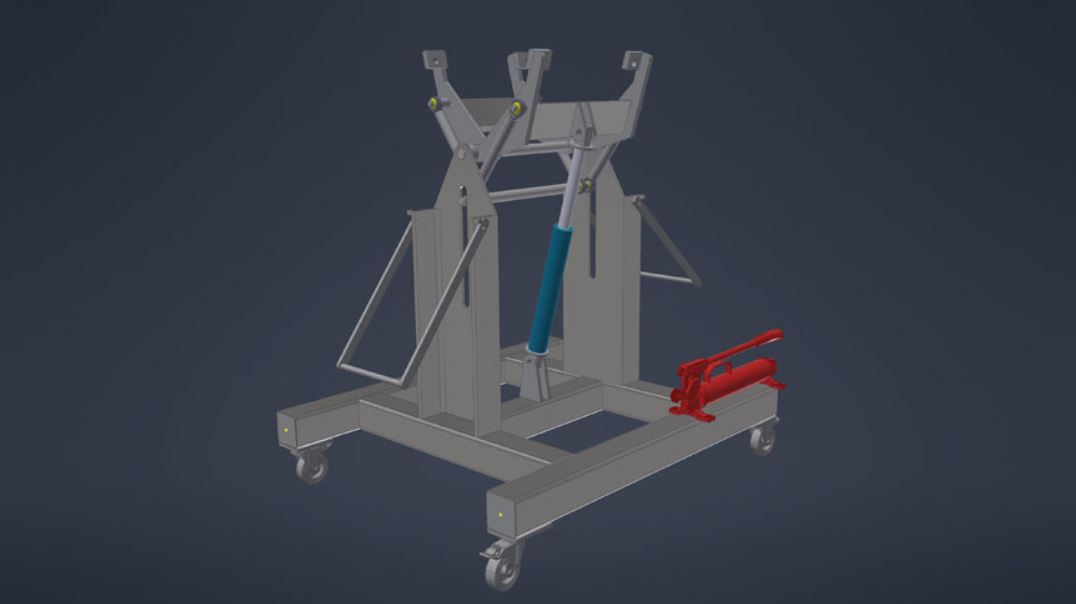

CAD software or CAD programs are widely used in various industries, including automotive, aerospace, architecture, manufacturing, and more. With CAD software, designers can create 2D or 3D models of products, parts, or structures, simulate their performance, test their functionality, and optimise their design before they are physically manufactured. This not only saves time and costs but also reduces the risk of design errors and allows for greater innovation and customisation.

Most CAD software offers a wide range of features and capabilities, making it a versatile tool for a multitude of design applications. Some of the basic features of CAD software include drawing tools, geometric modelling, dimensioning, and rendering. These features allow designers to create detailed and accurate designs, visualise them from different perspectives, and communicate their ideas effectively to clients or team members.

Advanced Features of CAD Software

In addition to basic features, most CAD software also offers advanced features that enhance the design process and improve productivity. These advanced features include parametric modelling, direct modelling, and specific features such as assembly modelling, sheet metal design, and simulation.

Parametric modelling is a powerful feature in CAD software that allows designers to create intelligent, associative models that capture design intent. Design intent refers to the designer’s original intent and specifications for the design, which can be modified or updated at any point in the design process. This feature enables designers to create complex and dynamic models that can be easily modified to accommodate changes in design requirements or specifications, saving time and effort in redesigning from scratch.

Direct modelling is another advanced feature in CAD software that allows designers to manipulate and modify 3D models directly without the need to edit the underlying feature history. This feature provides greater flexibility and speed in making design changes and modifications, allowing for faster design iterations and iterations.

Specific features in CAD software cater to specific industries or design applications. For example, assembly modelling allows designers to create complex assemblies of parts or components, simulate their interactions, and detect any interferences or conflicts. Sheet metal design is useful in the manufacturing industry, allowing designers to create accurate and efficient sheet metal parts and optimise their manufacturing process. Simulation features enable designers to test the performance and functionality of their designs under different conditions and scenarios, reducing the need for physical prototypes and testing.

Design Intent and Manufacturing Efficiency

One of the significant benefits of CAD design is the ability to capture and preserve design intent throughout the design process. Design intent refers to the original intent and specifications of the designer, which are embedded in the CAD model using parametric modelling. This means that any changes or modifications made to the model will update the entire design accordingly, ensuring consistency and accuracy.

Capturing design intent in the CAD model is particularly beneficial in the manufacturing process. Manufacturing involves converting digital design into physical products, and accurate and complete design information is crucial for ensuring manufacturing efficiency and quality.

Increased Efficiency with CAD Technology

CAD technology has revolutionised the way engineering and architectural drafting are done, providing increased efficiency in the design process. With CAD software or CAD programs, designers can create, modify, and optimise designs with precision and accuracy. The digital nature of CAD allows for quick iterations and modifications, reducing the time-consuming and costly process of manual design changes. Jarlam Australia, a leader in engineering and manufacturing, utilises CAD technology to streamline its design process and deliver innovative solutions to its clients.

Advanced Features of CAD Software for Enhanced Designing

Most CAD software offers advanced features that enhance the design process and improve productivity. Parametric modelling, a powerful feature in CAD software, allows designers to create intelligent, associative models that capture design intent. This enables designers to easily modify and update the design as per changing requirements, saving time and effort. Direct modelling is another advanced feature that allows designers to manipulate and modify 3D models directly without changing the underlying feature history. This provides flexibility and speed in making design changes, allowing for faster design iterations.

Specific features in CAD software cater to different industries and design applications. For example, assembly modelling allows designers to create complex assemblies of parts and simulate their interactions, helping detect any interferences or conflicts. Sheet metal design is useful in the manufacturing industry, enabling designers to create accurate and efficient sheet metal parts. Simulation features allow for testing the performance and functionality of designs under different conditions, reducing the need for physical prototypes and testing.

Capturing Design Intent for Manufacturing Efficiency

Design intent, which refers to the original intent and specifications of the designer, can be preserved throughout the design process using parametric modelling in CAD. This ensures that any changes or modifications made to the model are reflected throughout the design, maintaining consistency and accuracy. This is particularly beneficial in the manufacturing process, where accurate and complete design information is crucial for ensuring manufacturing efficiency and quality.

By capturing design intent in the CAD model, manufacturers can optimise their manufacturing processes. The digital design can be directly used for CNC machining, 3D printing, or other manufacturing processes, reducing the need for manual measurements and rework. Design intent also enables manufacturers to easily modify the design to accommodate different manufacturing requirements, such as material choices, tolerances, or production methods, without starting the design from scratch. This flexibility allows for efficient and cost-effective manufacturing, reducing production time and costs.

Customisation and Innovation with CAD Design

CAD design enables customisation and innovation, allowing businesses to create unique and innovative products. With CAD software, designers can easily modify and customise designs to meet specific requirements, such as size, shape, or functionality. This allows for personalised products tailored to individual customer needs, providing a competitive edge in the market. CAD design also fosters innovation, as designers can quickly test and simulate different design ideas, optimise them, and select the best design for production.

Jarlam Australia leverages CAD design to deliver customised solutions to its clients. Their team of skilled designers uses CAD software to create unique and innovative designs that meet the specific requirements of their customers. From complex machine parts to specialised components, CAD design allows Jarlam Australia to deliver high-quality products that meet their client’s exact specifications.

Improved Collaboration and Communication

CAD design enhances collaboration and communication among team members, clients, and stakeholders involved in the design process. CAD software provides tools for sharing and reviewing designs in real time, allowing for seamless collaboration among team members, even if they are located in different geographic locations. This promotes efficient communication and reduces delays in the design process.

Other Areas where Jarlam Australia Specialise in

-

Medical Technologies and Pharmaceuticals

-

Food, Fibre and Beverage

-

Defence & Defence Technologies

-

Recycling and Clean Energy

-

Primary and Secondary Packaging

-

And many more…

Contact our Team at Jarlam Australia.